Several weeks ago I had the privilege of presenting at Revit Technology Conference – North America 2016. My presentation frequently repeated the phrase “Because Nobody Went to Architecture School to…” We have all been there at some point in our career – continuously repeating the same manual alteration to a Revit model, changing parameter information one click-at-a-time, or performing tedious data entry for hours on end – these are the moments when you wonder if the practice of architecture is not exactly what you dreamed about in architecture school. For all the advancements that BIM has introduced to the AEC industry, production validation, and maintaining uniformity of the information are still difficult undertakings. Tasks that require hours and days of individual modifications are not always professionally rewarding and monopolize time that can better be spent on the overall quality of the design and documentation. I often tell colleagues that if you find yourself asking the question, “There has to be a more efficient way to do this”, chances are good that Dynamo can help.

I did not come from a computer programming background but instead began teaching myself Dynamo to address specific problems frequently encountered in Revit. After achieving a basic understanding of how Dynamo works, I was able to investigate tasks of increasing complexity that began with simple changes to the model and evolved to automating entire processes. As my Dynamo experience continued to grow I began exploring ways that Revit could interact with other software platforms and how data could be manipulated and visualized. My skillset eventually evolved to where I understood more advanced concepts of geometry and parametricism for design but this was all built on the foundational knowledge acquired from researching daily production tasks.

REVIT MODEL ANALYSIS

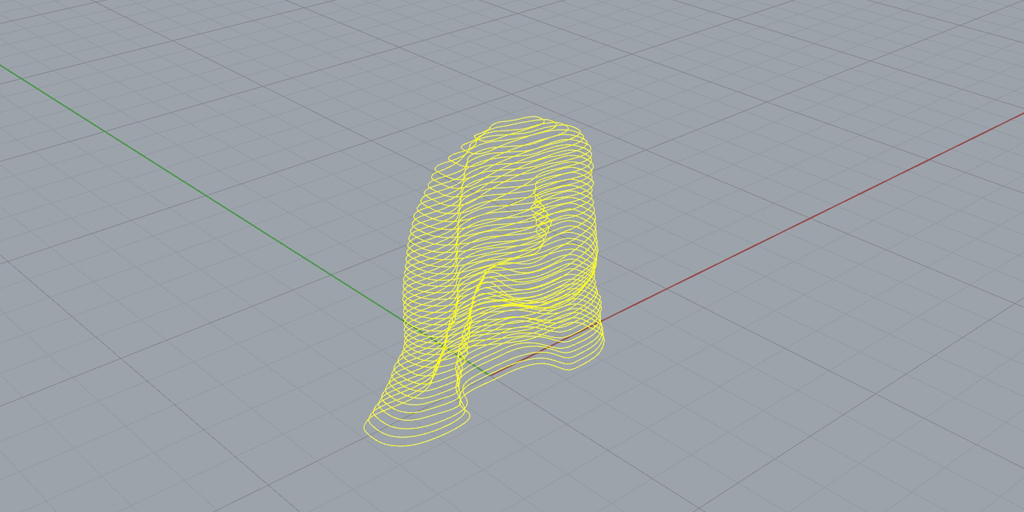

In my presentation I preceded to share a sample of workflows that respond to specific challenges encountered on projects and tell the story of tedious task automation and process improvement for architectural practice. A highlight was the opportunity to collect data on a very large healthcare project that I developed into a workflow for tracking Revit model metrics. The goal was to look for correlations between various model metrics and how long it takes to sync or open the model — one of the most significant factors of workshared projects because the extra seconds and minutes it takes to sync on a slow model multiplied by all the users on the project adds up to many hours of lost productivity over the course of the project. Dynamo is used to track the overall size of the .RVT file, query and count various elements and categories, parse the Warnings export file, then export all the information to an Excel file. In addition to collecting these general model metrics, the Dynamo task updated two additional spreadsheets with every warning in the model over time and every placed family in the model over time. All three of these of these spreadsheets were linked into Microsoft PowerBI along with data from imaginIT Clarity’s Model Metrics tool, which tracks the time it takes to open the model over time. Over the course of three months, I ran this Dynamo definition on a daily basis for a total of 68 exports.

The final takeaway will not be a surprise to those who are familiar with Revit model performance… the data revealed that Auditing and Compacting the model as well as Purging Unused Families had the most overall impact on the time it takes to open and sync the model. Although this may not be a significant breakthrough, these real-time analysis tools help monitor the health of the model and indicate when may be the best time to intervene.

The last step was to find an easy way to communicate the status of the model to the production team. Since it is the responsibility of the Model Lead on the project to audit the Central file, Warnings are the only characteristic that individual team members have the opportunity to impact. The project from which this data was collected happens to be a children’s hospital so we placed an image of a Minion on the Message Board with a visibility parameter tied to the number of Warnings. The final Dynamo task overwrites the Warning count parameter in the Revit model and the Minion changes accordingly. Now the team is aware that when they open the model at the beginning of a workday, if the Minion is purple the Warnings have exceeded 400 and some time needs to be set aside to resolve.

In the end RTC was an excellent experience. I thoroughly enjoyed sharing my perspective and bonding with my fellow colleagues from all over the world.

Special thanks to everyone who helped contribute to my work:

RTC & Committee

Shepley Bulfinch

Jim Martin

Jim Chambers

Jessica Purcell

Christina Tully

Margaret Gammill

PJ Centofanti

Jamie Farrell